On the igus website,

the customer can not only choose the right cable for their moving application

with the chainflex product finder, but also immediately configure their individual

energy chain system using the online e-chain expert, QuickChain.100. This

ensures reliable data on the durability of the e-chain and the cables, thus

making the selection of the most cost-effective system even easier.

With the motion plastics specialist igus, the

customer has now the opportunity to find the best energy chain system for a

travel of up to 100 metres more easily and quickly: Visit the igus website,

open the e-chain expert QuickChain.100 (QC.100), choose unharnessed or

harnessed cables, enter the application and environmental parameters and

finally select and configure the appropriate energy chain. Within the

QuickChain.100 expert, the user can choose from more than 1,200 highly flexible

chainflex cables tested by igus as well as over 4,000 'readycable' drive

cables. On the basis of the specified cables and application data, space

constraints, dynamics and energy chain environment, the customer can easily

choose from a range of 90,000 e-chains parts, which are tested in the in-house

laboratory spread over 2,750 square metres. The integrated service life

calculation for the energy chain and cables allows the customer to quickly and

easily choose the most cost-effective system that safely meets their

requirements. For customers trained by igus sales

staff, a "power mode" is also available, which allows interior

separations deviating from the standard recommendations for example the

stacking of up to three cables one above the other. This allows the customer to

choose a smaller e-chain width. Once the configuration has been completed, this

is checked again and approved by igus. The free e-chain expert QC.100

can be used both online and offline, alone and by a team. For example, several

team members from different departments can design energy chain systems online

at any time and at any place, process the CAD data and order them directly.

The e-chains expert QuickChain.100 is directly

available at https://www.igus.in/wpck/19139/N17_01_03_the_chain

About igus® India

igus®

operations in India started in the year 1998 with head quarters in Bangalore.

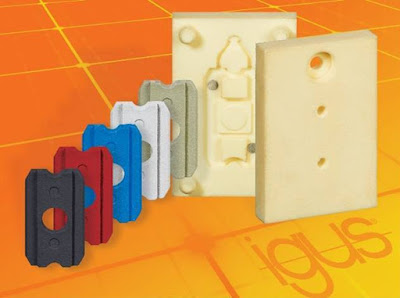

igus offers widest range of products that includes polymer bearings, igubal® Linear

Motion Bearings , Plain Bearings and Bushing

Accessories etc. which enable them to serve the whole industrial establishments

in India from a small work shop to huge industrial establishments.