A quick and safe energy and data transmission is

particularly important here. At the Hannover Messe, igus presents its

particularly versatile and forward looking cable solutions for use in the smart

factory. Along with the promise: "3 years' guarantee from the first

metre".

For

the factory of the future to work, a real-time communication of machines with

each other at all levels must be guaranteed. To ensure that all stations can

exchange their data with each other, Ethernet cables will be increasingly used

in factories. Not just on stationary, but also specifically in moving

equipment. For this reason, in the segment of copper-based Ethernet cables,

igus offers 23 different types, all of which are designed exclusively for

industrial, continuously moving applications, but also the most varied mechanical

requirements.

CAT7 Ethernet technology for

continuously moving applications

igus

will display its new CAT7 cable CFBUS.052 at the fair stand in Hannover . For substantially increasing data safety, it

has braided shields, pair shields and an overall braided shield with 90 percent

optical cover, which ensure functionality even after millions of bending cycles

in energy chains. The special core/braiding structure gives this CFBUS cable a

long-lasting flexural strength. "A braided shield made with an optimised

braid angle protects the overall shield against mechanical fractures as well as

the electromagnetic compatibility of the cable," explains Rainer Rössel,

head of the chainflex cables division at igus. The shielded pairs are stranded

with an optimised pitch length so that on the one hand they meet high

mechanical requirements, and on the other fulfil the electrical requirements in

terms of data transmission.

This

CAT7 cable is flame retardant like all highly abrasion-resistant TPE CFBUS

types. In addition, it has UL/CSA, EAC and CTP certifications and conforms to

DESINA. The new cable is furthermore for use in clean room environments

Fibre optic cables; communicate without

interference in highly dynamic applications

Due to

their immunity to electrical interference and the substantially higher data

capacity data transmission over fibre optic cables is of potential importance

for Industry 4.0. The range of fibre optic cables, which have also been

specially developed for continuous movement, covers all areas of mechanical

requirements. For example with the CFLG.2EC series, igus offers an affordable

fibre optic cable specifically designed for indoor use in handling or

woodworking machines. The CFROBOT5 enables robots to have fail-safe

communication in three-dimensional space. With the chainflex fibre optic cable

CFLG.LB.PUR, igus also presents a special fibre optic cable series for the

continuously moving application in the offshore and marine sectors. They are

already available with 2, 4 or 6 optical fibres or 2 optical fibres and 2 power

supply wires. The stranded-together multimode or single-mode fibres are very

bending-resistant types designed as a sub-cable, which can be fitted very

easily and cheaply with connectors. Due to its extremely high strength aramid

(Kevlar) braid over the overall stranding, even high tensile forces that may

occur in hanging applications do not damage the cable. The flame-resistant,

pressure extruded PUR outer jacket, especially tailored for energy chain use, provides

additional protection against external mechanical damage. Due to the DNV/GL

offshore approval, the new fibre optic cable family, as well as the CAT7 cable,

offers the capability to securely transmit data on offshore platforms and

ships.

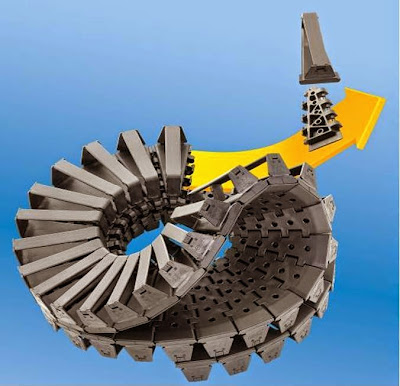

Image

PM1715-1

With the world's first CAT7 Ethernet cable for

the movement in energy chains, igus ensures secure data transfer in the factory

of the future. (Source: igus GmbH)

For more details

please visit: http://www.igus.in/wpck/11509/N14_2_0_Overview_CF?C=IN&L=en

From

the Hannover Messe onwards, igus offers a 36-month guarantee for all cables

from the first ordered metre.

About igus India