Optimum use of installation space, light weight and high stability -

these are just some of the benefits of the E4.1L energy chain from igus, which

is now available in new heights and widths from stock. Compared to the E4.1, weight

can be reduced by 30 percent, with this light version, meaning that the chain

is well suited to highly dynamic applications. It was developed especially for

unsupported applications; long gliding travels are also possible with the

e-chain.

The E4.1L

of the motion plastics specialist igus combines the strengths of different

series of chains from igus and also has a design that is very kind to all the

surfaces in contact with the cables. "Rounded edges of the crossbars and

separators of the chain ensure a long service life of hoses and cables,"

explains Harald Nehring, authorised representative for e-chain systems at igus.

"You can therefore call E4.1L an energy chain in which the moving cables

feel at ease." In addition to the rounded surfaces that come in contact

with cables, gridding and positioning scales are used for the best possible

separation of the chain. Along with the easy assembly and high stability it

displays its strengths especially in fast unsupported applications, such as in

automation or in machine tools.

Technical tricks for design freedom

The simple

snap-open mechanism of the crossbars in the outer and inner radius ensures a

quick filling of the e-chain. The captive crossbars, which can be opened with a

screwdriver, open by 115 degrees and latch into final position. If necessary,

they can even be removed completely, placed again and closed by simply pressing

in. The patented positive-fit tongue and groove of the chain links and the

double stop dogs with large stop surfaces that allow a high degree of stability

were carried over from the heavy duty E4.1 chain. Here a 'brake' also ensures a

lower rolling noise and a very smooth chain travel. Due to the variable

mounting of the outer links, the chain can be installed either with or without

camber. This is a decisive advantage especially in limited installation space,

such as in machine tools.

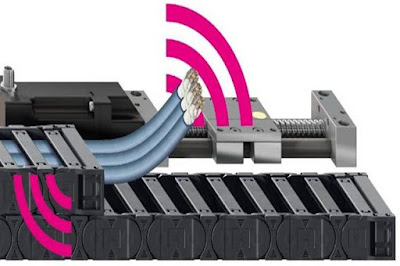

Picture

PM1016-1

Due to the modular design, the E4.1L energy chain

can be adapted to any specific application. As an open standard version for

cable routing, with brackets for hoses, or enclosed in a chip-resistant tube in

a guide trough – just three of many customising options. (Source: igus GmbH)

"Perhaps the best e-chain in the world"

Compared to

E4.1, the application-oriented design of the E4.1 L could save so much mass

that the chain is about 30 percent lighter. This brings an additional

advantage: "In this way, users save not only a lot of drive power,"

says Harald Nehring. "It can also accommodate more hoses and cables in a

given space envelope – all these advantages perhaps make the E4.1L the best

e-chain in the world." The energy chain is now available from stock in

more interior heights between 31 and 64 millimetres and new widths, as well as

fully enclosed options for the protection against chips. As for the open energy

chain, igus also has an ESD version and even a high-temperature option for the

enclosed energy tube.

For more information please visit: http://www.igus.in/energychains?C=IN&L=en