igus

has given its micro-chains for tight design spaces a makeover and come up with

a new modular system: clever design tricks such as the double stop system or

the “brake” make the E2 micro versions even sturdier and quieter than their

predecessors. With the e-chain E2.15 an increase in possible additional load of

100 per cent was achieved. With a self-supporting length of the upper run of up

to 1.25 m, new application options are now possible in the tightest of spaces.

The

micro-chains from igus are made up of very small one or two-part e-chains.

Their low weight makes them extremely suitable for highly dynamic applications such

as automatic doors, measuring machines, handling, pick-and-place robots or

adjusting units.

Picture -01

Every E2 micro-chain is delivered with a plastic opening tool. The wings are hinged at the side and open all bridges in seconds for even faster installation.

With

the series E2.10 and E2.15 the tribo-polymer company from Cologne has developed

a new generation of micro-chains. The new energy chains are much

sturdier than their same-size predecessors. The high stability is due in part

to the clever design – a double stop system helps the E2.15 series to achieve

an increase in possible additional load of up to 100 per cent. And with a

maximum self-supported length of 1.25 m, 25 per cent more than with the

predecessor chain, new application possibilities are possible even where space

is extremely tight. New in the modular system are the micro-separating bridges,

the catches of which guarantee a firm hold even with side fixtures. In

addition, the round contours of the bridges ensure a particularly smooth

interior that goes easy on the cables. A built-in “brake” dampens stop noises

and guarantees smooth running.

Opening

tool for assembly in seconds

The E2 micro system includes connection elements in different versions –

rigid, one-sided and two-sided pendulum bearings. This means the E2 micro can

be mounted in any direction on the chain and attached to the machine –

including on the front when the quick flange clipped in at the side is used.

This allows the E2 micro to be used for all applications – horizontally,

vertically downwards or upwards, circular or even lateral.

A

further aspect of the new E2 micro is its fast and easy installation. There is

an entering diagonal worked into the bolts of the sides to make assembly

easier. Every E2 chain is delivered with a plastic opening tool to make

installation even faster. The tool can be hinged open at the side and has wings

which open all the bridges in seconds.

Modular

system also for the smallest e-chains

The

new e-chains differ from their one-part predecessors in terms of design too,

the E2 micro system is available in the igus-specific modular range in three

variants: Alongside a completely closed version, the E2 micro can be opened

with two different bridge versions in the outer or inner radius. At the moment,

all versions with an inner width of 20 mm for the heights 10 mm and 15 mm are

available. Gradually, after the Hanover Fair, both series will be manufactured

in seven further widths each.

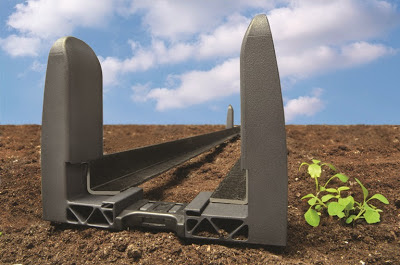

Picture -02

The new generation of igus micro-chains is even sturdier than its same-size predecessors: With the e-chain E2.15 a few design features achieved an increase in possible additional load of 100 per cent.

About

igus India;

igus®

operations in India started in the year 1998 with head quarters in Bangalore. igus

offers widest range of products that includes polymer bearings,

igubal® spherical bearings, DryLin® linear bearings & guide systems enable them

to serve the whole industrial establishments in India from a small work shop to

huge industrial establishments.